MACRO-EPOXY.

Macropoxy Aluminum Protection Coating

Offered by Linings Inc. | Powered by Sherwin-Williams

When it comes to protecting your investment, Linings Inc. delivers more than just industry-leading dump body liners—we now offer a powerful corrosion-resistant solution for the aluminum beneath them.

Why Macropoxy?

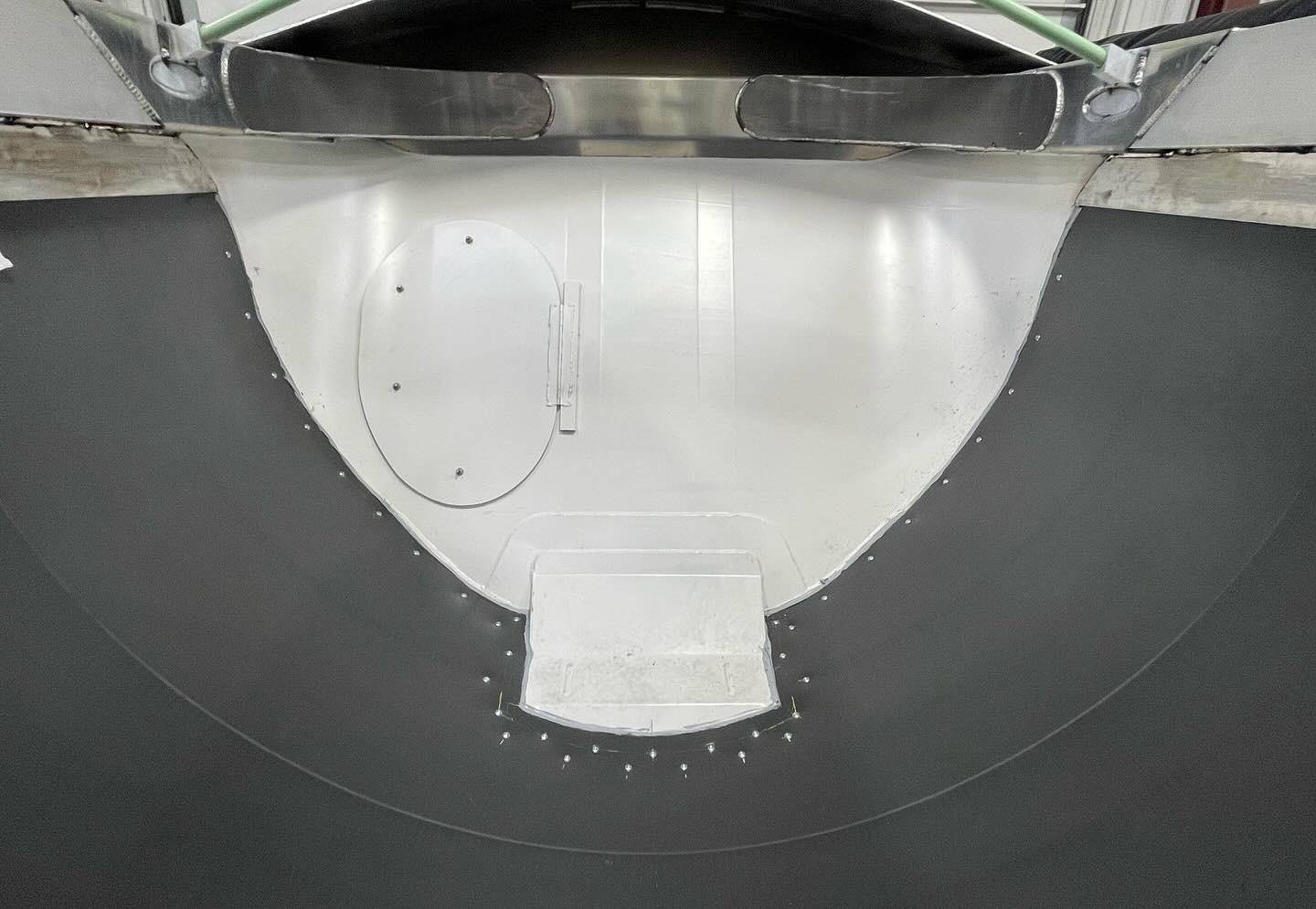

Our Macropoxy system is a two-part, spray-applied epoxy coating developed in partnership with Sherwin-Williams. Designed specifically for haulers of corrosive materials like fertilizers, this protective layer shields the aluminum floor beneath your liner from chemical attack and premature deterioration.

- Anti-Corrosive Barrier: Forms a durable, chemical-resistant layer between the aluminum and any trapped material.

- Spray-On Application: Ensures even coverage and strong adhesion to aluminum surfaces.

- Non-Wear Zone Protection: Applied only beneath the liner—no interference with liner performance or wear zones.

- Preventative Maintenance: Reduces the risk of floor damage caused by trapped materials during unloading or tailgate closure.

Application Process

Our trained technicians follow a meticulous process:

- Surface Prep: Aluminum is cleaned with acetone and masked to protect non-coated areas.

- Spray Application: Macropoxy is applied using professional-grade sprayers for uniform coverage.

- Cure & Install: Once cured, your liner is installed over the protected surface, locking in long-term durability.

Proven Performance

Customers hauling corrosive loads have reported excellent results, with many opting to coat all future units before liner installation. This solution is ideal for:

- Fertilizer haulers

- Agricultural and chemical transport

- Any application where corrosion beneath the liner is a concern

Ready to Protect Your Fleet?

Contact Linings Inc. today to learn more about adding Macropoxy protection to your next liner installation. We’ll coordinate transportation, installation, and even work with your tarp shop to streamline the process